FACTORY

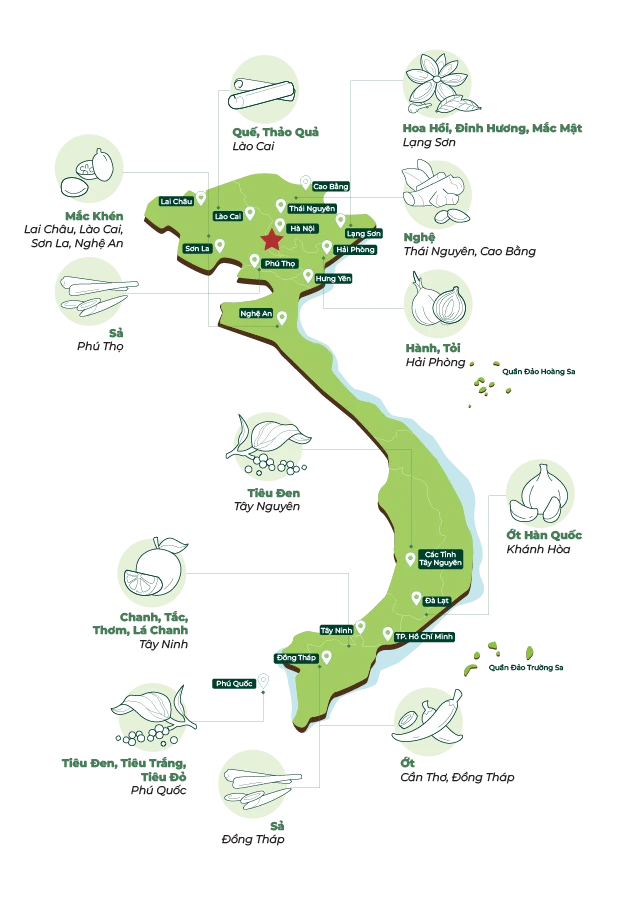

Control of input materials

Establish a material control process

100% of raw materials, packaging, labels and means of transport must be inspected by QC before being put into storage, based on Vietnamese principles and standards (TCVN) on sampling procedures. The inspection method must include full sensory properties (color, smell, taste,...), weight, size and damage rate.

Establish a periodic supplier evaluation process

Before purchasing: Service and goods suppliers must be assessed based on global standards recognized by GFSI.

After purchasing: The Purchasing Department conducts periodic supplier evaluations at least once a year, based on criteria such as quantity accuracy, product quality, delivery time, and level of cooperation.

Establish procedures for handling non-conforming shipments

Shipments that do not meet the standards will be rejected for warehouse entry. The Purchasing Department will send feedback to the supplier and implement appropriate handling measures according to the prescribed procedures.

Production process control

BRCGS Certification (Version 9.0)

ISO 22000:2018 Certification

HACCP Certification

GACC code granted

Jakim Halal Certification

Control output products